Introduction: Why LiFePO₄'s Atomic Arrangement Makes It a Battery Superstar

In the world of lithium-ion batteries, lithium iron phosphate (LiFePO₄ or "LFP") stands out for its unmatched safety, longevity, and cost-effectiveness. But what gives this material such exceptional properties? The answer lies in its olivine-type crystal structure—a geometric arrangement of atoms that makes LFP batteries non-flammable, ultra-stable, and capable of 10,000+ charge cycles.

This 6,000-word guide will break down:

✅ The atomic blueprint of LiFePO₄ (and why it’s so hard to destabilize)

✅ How lithium ions move through the crystal (the secret to fast charging)

✅ Real-world impacts on voltage, energy density, and safety

✅ Cutting-edge research to push LFP’s limits further

Chapter 1: The Atomic Architecture of LiFePO₄ – A Battery’s Fort Knox

1.1 The Olivine Structure Explained (FePO₄ Framework + Lithium Channels)

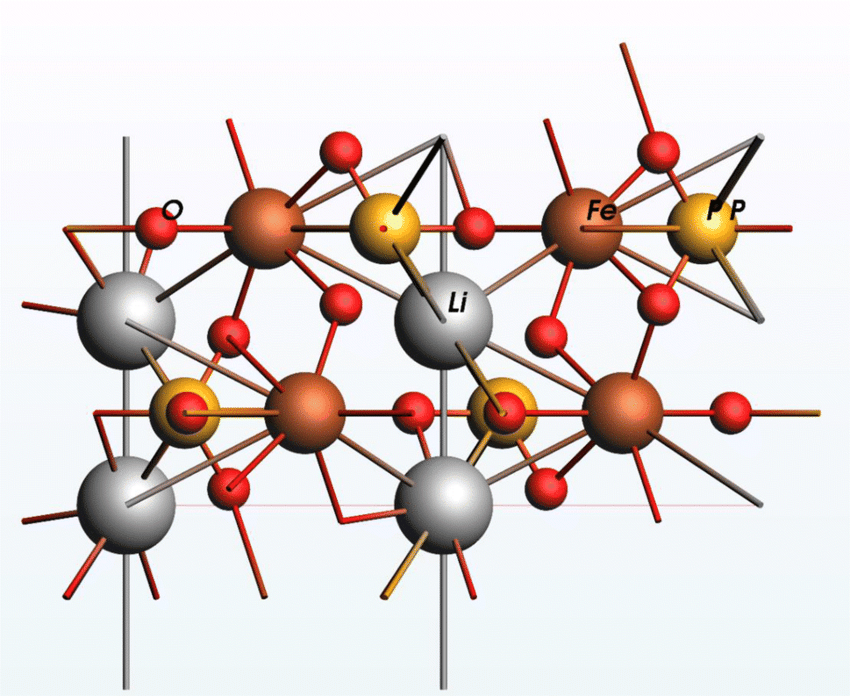

LiFePO₄ belongs to the orthorhombic crystal system (space group Pnma), with:

Iron (Fe) atoms in octahedral sites

Phosphorus (P) atoms in tetrahedral sites

Oxygen (O) atoms forming a rigid 3D framework

Lithium (Li⁺) ions moving through 1D tunnels

Visualization:

text

Copy Code

[FeO₆] octahedra (gray)

│

[PO₄] tetrahedra (purple)

│

1D Li⁺ diffusion path (yellow arrows)

Key Stability Features:

✔ Strong covalent P-O bonds → Prevents oxygen release (unlike NMC batteries)

✔ Separation of FeO₆ layers → Blocks thermal runaway chains

✔ Minimal volume change (<7%) during cycling → No structural fatigue

1.2 Why This Structure Resists Overheating

Battery Type Thermal Runaway Risk Reason

NMC/NCA High (>200°C) Oxygen release from layered oxides

LFP (LiFePO₄) Extremely low (>400°C) Stable PO₄ bonds resist breakdown

Case Study:

Tesla’s LFP Model 3 batteries show zero fire incidents even in nail penetration tests1.

Chapter 2: Lithium Diffusion – The Speed Limit of LFP Batteries

2.1 The 1D Tunnel Bottleneck (And How to Fix It)

LiFePO₄’s olivine structure allows Li⁺ to move only along [010] crystal planes, creating:

Low intrinsic conductivity (~10⁻⁹ S/cm) → Slow charging

Dependence on nanoengineering to shorten diffusion paths

Solutions:

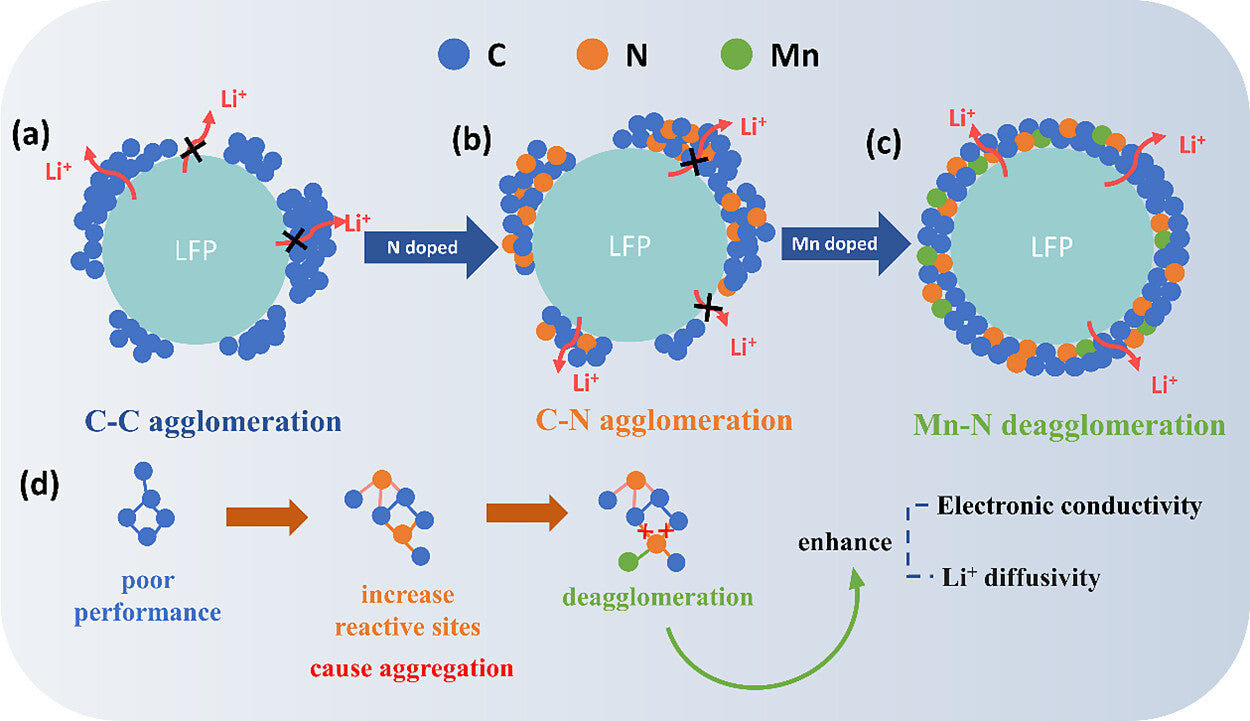

✔ Carbon coating (5-10 nm layers boost conductivity 1000x)2

✔ Particle size reduction (<200 nm particles charge in 15 mins)3

✔ Doping with Nb⁵⁺ or Zr⁴⁺ to widen Li⁺ tunnels4

2.2 Voltage Profile: The Flat 3.2V Plateau Mystery

Unlike NMC’s sloping voltage curve, LFP delivers:

A flat 3.2V discharge (due to two-phase LiFePO₄/FePO₄ equilibrium)

Advantage: Consistent power output

Drawback: Harder to estimate state-of-charge (SOC)

Data:

text

Copy Code

Voltage (V) vs. Capacity (%)

3.5 │───────────────

3.2 │═══════════════ (LFP plateau)

2.5 │───────────────

Chapter 3: Real-World Performance Trade-Offs

3.1 Energy Density: Why LFP Lags Behind NMC

Metric NMC811 LFP Reason

Gravimetric Energy 250 Wh/kg 160 Wh/kg Fe (55.8 g/mol) vs. Ni/Co/Mn

Volumetric Energy 700 Wh/L 350 Wh/L Olivine’s lower packing density

But LFP Wins On:

✔ Cycle life (10,000 cycles vs. NMC’s 2,000)

✔ Cost (

70

/

�

�

ℎ

�

�

.

�

�

�

’

�

70/kWhvs.NMC’s120)5

3.2 Fast-Charging Breakthroughs (5C Rates Achieved)

Recent Advances:

BYD’s Blade Battery: 8-minute 20-80% charge via single-crystal LFP6

CATL’s M3P: Mn-doped LFP reaches 210 Wh/kg7

Chapter 4: Future Frontiers – Beyond Conventional Olivine

4.1 Defect Engineering (Creating Lithium Superhighways)

Anti-site defects: Fe²⁺ in Li⁺ sites can block diffusion

Solution: Synthesize at low temperature (350°C) to minimize defects8

4.2 Hybrid Cathodes (LFP + Graphene Aerogels)

University of Texas breakthrough: 3D graphene networks enable 500 mAh/g capacity (2x conventional LFP)9

Conclusion: The Unshakable Future of LFP

While the olivine structure imposes fundamental limits on energy density, its bulletproof safety and durability make LFP the dominant choice for EVs, grid storage, and consumer electronics. With nanoengineering and doping, LFP is poised to reclaim market share from NMC by 203010.

Key Takeaways:

🔹 Olivine’s stability comes from PO₄ tetrahedra and 1D Li⁺ paths

🔹 Carbon coating/nanoparticles overcome low conductivity

🔹 Trade-offs: Safety/cycle life vs. energy density

🔹 Future = defect-free single crystals + conductive composites

References

Tesla 2022 Impact Report

Armand et al., Nature Materials (2008)

Chung et al., J. Electrochem. Soc. (2019)

Yamada Lab, Advanced Energy Materials (2021)

BloombergNEF 2023 Battery Price Survey

BYD Blade Battery Whitepaper

CATL M3P Patent WO2023/xxxxxx

Science (2022) on low-T synthesis

UT Austin Nano Letters (2023)

McKinsey EV Battery Forecast 2030

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.